Architectural Design

Additions, new construction, interiors, and refurbishments — BIM-first delivery.

How It Works

- Discovery: client goals, constraints, code checks, and site context.

- Concept and options: massing, façade studies, interior flows, materials.

- Design development: coordinated Revit model (arch/struct/MEP envelopes).

- Construction documents: plans/sections/elevations, schedules, details, BOQs.

- Support: coordination during construction and as‑built updates.

A Plain‑English Overview

Many homeowners and developers know they want more light, better flow, or a new addition, but are unsure how that turns into drawings and a built result. I guide you from ideas to a permit‑ready package and beyond. We begin by capturing your wishes and constraints, then translate them into clear spatial options that you can react to. Each option includes simple pros/cons—budget impact, buildability, and how it feels to live in. Nothing technical yet; the goal is clarity and confidence.

Once a direction is chosen, I build a coordinated 3D model in Revit. This is the single source of truth that drives plans, sections, elevations, schedules, and render views. Because everything is connected, changes are consistent everywhere. I coordinate the structure and mechanical needs early (beam depths, ceiling space, duct runs) so we don’t discover conflicts on site. When we issue drawings, they are accurate because they’re generated from the model you have reviewed.

Step‑by‑Step Walkthrough

1) Discovery. We discuss goals, style, spaces you need, and constraints (site, zoning, HOA, budget, schedule). I study available surveys or existing drawings and perform quick code checks. The output is a short brief we both agree on and a plan for the next reviews.

2) Concepts. I create 2–3 viable concepts. Each covers overall layout, massing, window strategy, and how you move through the home. You’ll see views and simple renderings that focus on proportion, light, and relationships—not finishes yet. We keep the best parts and decide on a direction.

3) Design Development. I refine rooms and envelopes, introduce realistic finishes, and coordinate structural spans and service zones. The model now supports dimensioned drawings and schedules. We lock the main assemblies so costs and lead times can be checked.

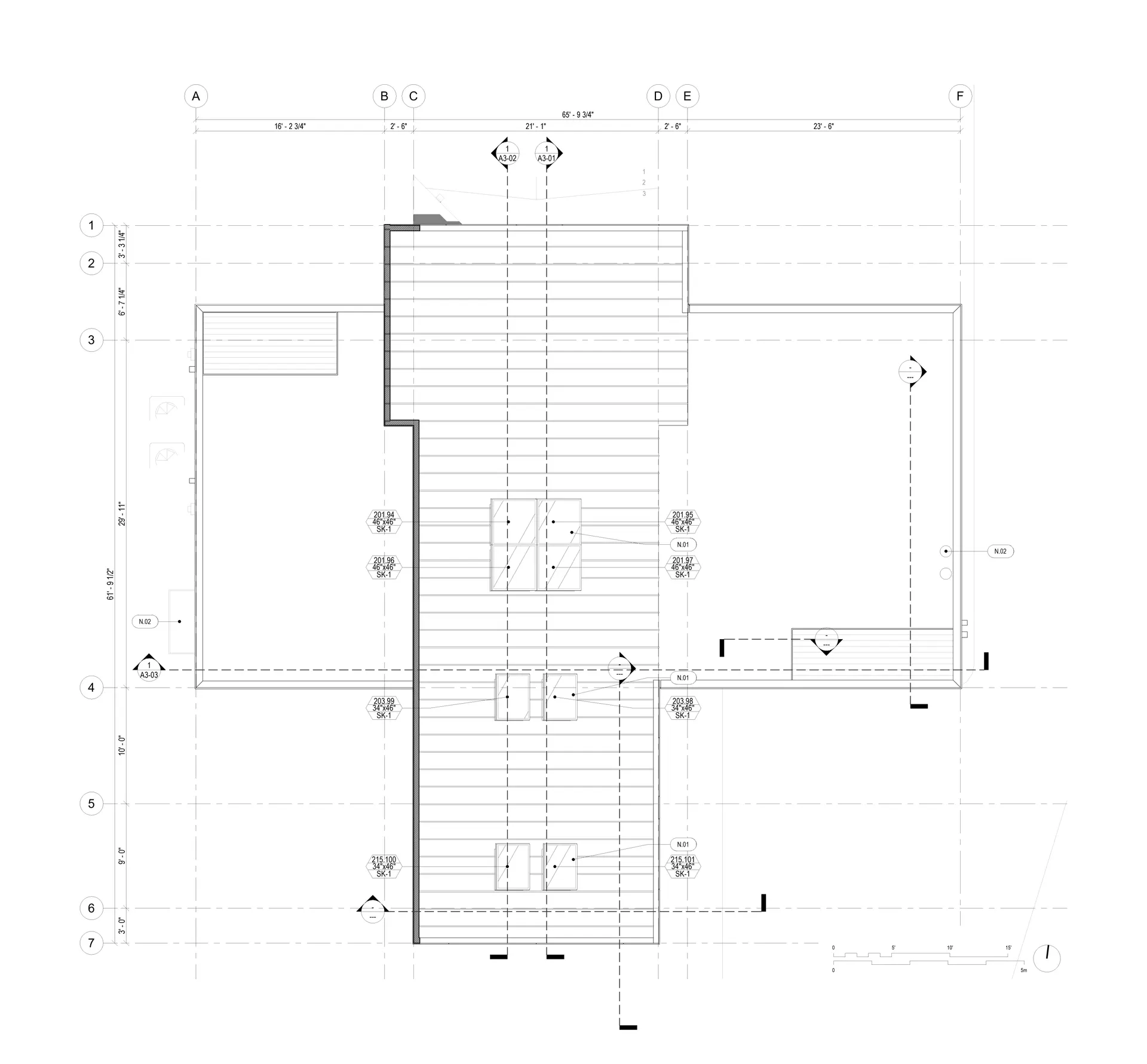

4) Construction Documents. I produce the full set: plans, sections, elevations, typical details, and schedules. Because they come from the model, they are internally consistent. I include key notes and call‑outs contractors expect, and align sheets to your permitting requirements.

5) Construction & As‑Builts. I stay available for RFIs and adjustments. When the work is complete, I update the model to what was built and deliver an as‑built set—useful for future work and facility records.

What You Can Expect

- Clear options early (with pros/cons and indicative costs) so you can decide with confidence.

- A clean Revit model that drives drawings, schedules, and visuals—no 2D/3D drift.

- Regular check‑ins and coordination with structure/MEP to avoid late surprises.

- Permit‑ready CDs with consistent sheets, details, and code information.

- As‑built updates after construction for a reliable record model.

Deliverables by Phase

- Concept: massing views, key plans/sections, façade studies, mood boards.

- Design Development: coordinated model, room/area schedules, typical details.

- Construction Documents: full plan/section/elevation set, door/window schedules, finish schedules, details, BOQs.

- Construction Support: revisions/addenda, RFIs, site clarifications.

- As‑Built: updated model and drawing set reflecting field conditions.

Inputs Needed

- Brief and priorities (program, style references, budget, schedule).

- Site information and survey; any HOA or local code constraints.

- Existing drawings or photos (for additions/renovations).

Process & Timeline

Typical single‑family projects run 6–12 weeks design + 4–8 weeks CDs, depending on scope and permitting. Larger or multi‑unit projects scale accordingly. You will receive a simple schedule with review milestones.

Site, Code, and Context

Every project is anchored in context. Before drawings are produced, the site is reviewed through its physical characteristics (orientation, slope, utilities), regulatory environment (zoning setbacks, height and lot coverage limits, overlays), and neighborhood fabric (scale, rhythm, privacy, and material cues). This early understanding prevents concepts that look appealing on paper but cannot be permitted or will be costly to construct. For additions and interior refits, the existing structure is documented sufficiently to understand bearing conditions, floor levels, and points where services can route without compromising headroom or envelope integrity. These steps are designed to reduce risk and frame the opportunity space realistically from the beginning.

A practical example: a rear addition that aims to maximize glazing may conflict with required rear yard setbacks or energy compliance. Rather than postpone that discovery, constraints are translated into dimensional guardrails that shape the concept. Similarly, if soils indicate deep footings or the presence of rock, structural strategies consider these factors so that later engineering aligns with the architectural intent. The goal is not to over‑engineer early, but to draw within parameters that are likely to hold through permitting and construction.

Light, Comfort, and Flow

A successful plan feels easy to live in. Circulation is intuitive; natural light reaches deep into the plan; and sightlines frame views rather than broadcasting clutter. In concepts, window positions and sizes are not arbitrary—they are set to capture light at different times of day, protect privacy, and balance thermal performance with visual comfort. Stair placement considers how family members move between zones, reducing unnecessary travel while providing clear separations between public and private areas when desired. These decisions are explained in review packages with simple diagrams, so you can evaluate not only how a space looks, but how it works.

For interiors, ergonomics are treated as first‑class design criteria. Kitchens are laid out by work patterns and clearances; bathrooms by fixture spacing and maintenance access; storage by actual use patterns rather than leftover niches. The discipline is to make beautiful spaces that are also comfortable and efficient to use daily.

Envelope, Structure, and Services

Architecture, structure, and MEP are developed together. The model carries the envelope (walls, roofs, insulation strategies), but the geometry anticipates framing depths, beam lines, and service zones. Typical coordination items include window head heights vs. lintel sizes, duct bulkheads vs. ceiling drops, and the placement of vertical risers that minimize turns while staying within wall cavities or dedicated chases. These checks are built into the weekly rhythm so that design decisions keep construction in mind and avoid late compromises.

In climates where performance matters, the envelope is detailed to control air and moisture while remaining buildable with local trades. Wall types and roof assemblies in the model include the layers necessary to communicate intent, and details are added where transitions are prone to misinterpretation: sill and head conditions, parapets, and roof‑to‑wall interfaces. The benefit is fewer assumptions by contractors and a smoother path through submittals.

Materials, Finishes, and Procurement

Finishes are selected with availability and lifecycle in mind. The documentation indicates not only the look, but also the typical size, installation pattern, and transitions to adjacent materials. Where a finish drives coordination—tiled niches, stone thresholds, integrated lighting—the detail is captured in the set so procurement decisions align with the physical reality on site. Schedules are generated from the model, making quantity take‑offs more reliable and helping contractors plan lead times.

When clients wish, a tiered approach is offered: a base specification that achieves the design intent with good value, and optional upgrades that can be priced without replanning the layout. This enables clear trade‑offs between cost and experience without restarting the design process.

Digital Workflow and Quality

The digital process is deliberately simple for clients yet rigorous behind the scenes. Revit is used for authoring, with view and sheet templates ensuring consistent graphics. Naming, shared parameters, and coordinate systems are standardized so files can be exchanged with engineers and contractors without friction. For visualization, selected views are rendered directly from the model; for complex light or material studies, external tools are invoked as needed, but the model remains the single point of coordination. Model health is monitored through warnings and periodic audits; families are kept lean to maintain performance.

Before each issue, a QA pass checks correctness (dimensions, tags, schedules) and completeness (are the details necessary for pricing and constructing present?). The objective is to send information that is buildable and traceable, reducing back‑and‑forth and the potential for field changes.

Communication and Decision Making

Communication is structured to respect your time while keeping momentum. Each review package includes a concise cover note, a small set of views that illuminate the current decisions, and a short list of items parked for later phases. When helpful, annotated videos are recorded to walk through the model. Decisions are tracked, and the model is updated immediately after reviews so that the next package reflects the latest agreements.

For projects with multiple stakeholders, a shared dashboard can summarize status: upcoming decisions, coordination items, and the path to permit. This transparency keeps teams aligned and reduces the risk of parallel changes that conflict.

After Approval: Construction Support

During construction, questions are inevitable. Support focuses on clarity and speed: RFIs receive references to drawing numbers and, when necessary, a small detail or sketch that removes ambiguity. Minor changes are incorporated into the model so that schedules and quantities remain aligned. At the end of construction, the as‑built update provides a faithful record of what was built, including any substitutions or field‑approved changes, which is invaluable for operations or future work.